BATTERY — LEAD-ACID TYPES - All Models

The range of Lucas batteries listed here covers those models fitted to B.S.A. motor cycles in recent years.

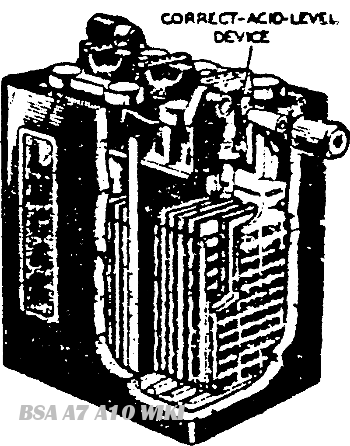

Fig. Y 18. Sectioned battery, model PU7E/9

|

PU5E and LVW5E

|

Small capacity batteries for light-weight machines. |

|

PU7E

|

Standard battery for cradle mounting. |

|

GU11E

|

Larger capacity battery for sidecar machines. |

|

SC7E

|

Large capacity lightweight battery for machines fitted with starting motors or two-way radio equipment, e.g. police machines. |

All current Lucas motor cycle batteries are "dry charged", and do not require initial charging. Except that these batteries have porous rubber separators, they are identical with earlier models supplied wet or uncharged and require the same routine maintenance when in service.

Storage

Used batteries must be fully charged before storing. In temperate climates they should be examined fortnightly, or weekly in the case of model LVW5E and all models when stored in the tropics. If necessary, give them a short refreshing charge.

After a long period of storage, the condition of the battery will often improve if it is put through a "cycle". as described

Maintenance

Every fortnight, or more frequently in hot climates, examine the condition of the battery. Examine five-plate batteries every week.

Never use a naked light when examining the condition of the cells, as there is a danger of igniting the gas coming from the active materials.

Cleaning

Remove the battery cover and clean the cell tops Examine the connections. If they are loose or dirty, remove them and scrape the contact surfaces clean. Coat them with petroleum jelly before replacing.

Remove the filler plugs and check that the vent holes are clear and that the rubber washer fitted under some plugs is in good condition.

Topplng-up

During charging, water is lost by gassing and evaporation. Examine the electrolyte level in each cell and, if necessary, add distilled water to raise the electrolyte level with the top edges of the separators.

SC7E batteries have a woven glass pad fitted in each cell to reduce splashing when the battery is gassing during charging. When 'topping-up' this type of battery, it is useful to note that the correct electrolyte level is reached when moisture appears through the porous glass pad.

The Lucas Battery Filler

The use of a Lucas motor cycle Battery Filler will be found helpful in this 'topping-up' process. as it ensures that the correct electrolyte level is automatically attained and also prevents distilled water from being spilled over the battery top.

Correct-Acid-Level-Devices

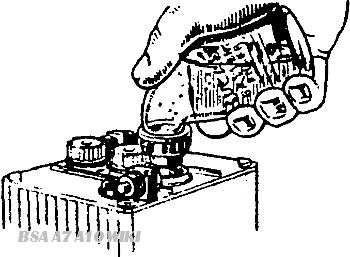

Fig Y19. The Lucas battery filler

The Correct-Acid-Level-Device fitted to some Lucas batteries consists of a central tube with a perforated flange which rests on a ledge in the filling orifice. When 'topping-up' a battery fitted with these devices, pour distilled water round the flange (not down the tube) until no more drains through into the cell. This will happen when the electrolyte level reaches the bottom of the central tube and prevents further escape of air displaced by the 'topping-up' water. Lift the tube slightly to allow the small amount of water in the flange to drain into the cell. The electrolyte level will then be correct.

If a battery requires "topping-up" too frequently, the voltage regulator (on machines fitted with d.c. generators) may be out of adjustment, i.e. set too high, and should be checked. Conversely, a persistently low state of charge may be due to a regulator being set too low.

If one cell in particular needs 'topping-up' more than another, it is likely the container is cracked, in which event replace the battery and clean the carrier, using a solution of ammonia or bicarbonate of soda in water. After cleaning and drying, paint the battery carrier and other surfaces affected by the electrolyte with anti-sulphuric paint.

TABLES OF SPECIFIC GRAVITIES AND CHARGING RATES

|

Battery

|

Plates per cell

|

Amp. Hr. Capacity

|

Electrolyte to fill one two-volt cell

|

Home Trade and Climates Ordinarily below 90°F. (32BC.) Specific Gravity of Acid (corrected to 60°F.)

|

Climates frequently over 90°F. (32°C.) Specific Gravity of Acid (corrected to 60°F.)

|

Initial Charge Current

|

Re-charge Current

|

||||

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

||

|

At 10 hour rate

|

At 20 hour rate

|

Pint

|

C.C.

|

Filling

|

Fully Charged

|

Filling

|

Fully Charged

|

Amp.

|

Amp.

|

||

|

LVW5E

|

5

|

5

|

5.7

|

1/8

|

71

|

1.270

|

1.270 -1.290

|

1.210

|

1.210 -1.230

|

0.3

|

0.5

|

|

PU5B

|

5

|

8

|

9

|

1/6

|

94

|

1.270

|

1.270 -1.290

|

1.210

|

1.210 -1.230

|

0.6

|

1.0

|

|

PU7E

|

7

|

12

|

13.5

|

1/5

|

113

|

1.270

|

1.270 -1.290

|

1.210

|

1.210 -1.230

|

0.8

|

1.5

|

|

GU11E

|

11

|

20

|

22.8

|

1/3

|

189

|

1.270

|

1.270 -1.290

|

1.210

|

1.210 -1.230

|

1.3

|

2.2

|

|

SC7E

|

7

|

22.5

|

26

|

250

|

1.270

|

1.270 -1.290

|

1.210

|

1.210 -1.230

|

1.5

|

2.5

|

|

The maximum permissible electrolyte temperature during charging is given below. Should the temperature of the electrolyte exceed this value interrupt the charge and allow the battery temperature to fall at least 10°F. (5.5°C.) before charging is resumed.

|

Climates normally below 80°F.

(27°C.)

|

Climate between 80"-100°F.

(27-38C.)

|

Climates frequently above 100°F.

(38"C.)

|

|

100"F. (38°C.)

|

110"F.(43-C)

|

120"F. (49"C.

|

The specific gravity of the electrolyte varies with temperature. For convenience to comparing specific gravities, they are always corrected to 60°F.. which is adopted as the reference temperature. The method of correction is as follows:

For every 5°F. below 60°F.. deduct 0.002 from the observed reading to obtain the true specific gravity at 60°F. For every 5°F. above 60°F.. add 0.002 to the observed reading to obtain the true specific gravity at 60°F.

The temperature must be that indicated by a thermometer having its bulb actually immersed in the electrolyte, and not the ambient temperature.

SERVICING

Battery Persists in a Low State of Charge

first consider the conditions under which the battery is used. If the battery is subject to continuous discharge, e.g. long periods of night parking with lights on without suitable opportunities for recharging, a low state of charge is inevitable.

A fault in the dynamo or regulator, or neglect during a period out of commission, may also be responsible.

Vent Plugs

See that the ventilating holes in each vent plug are clear, and that the rubber washer fitted under the plug is in good condition.

Level of Electrolyte

The surface of the electrolyte should be level with the tops of the separators, if necessary, top-up with distilled water. Any loss of acid from spilling or spraying (as opposed to normal loss of water by evaporation) should be made good by dilute acid of the same specific gravity as that already in the cell.

Cleanliness

See that the top of the battery is free from dirt or moisture which might provide a discharge path. Check that the battery connections are clean and tight

Hydrometer Tests

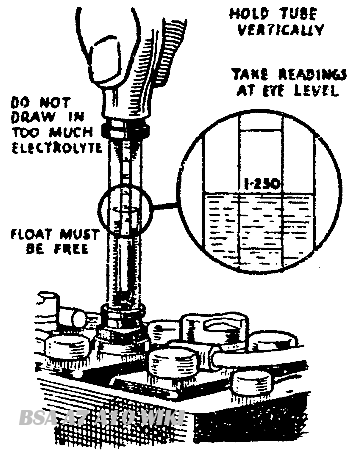

Fig. Y20. Taking hydrometer readings

The space between each separator is not wide enough to permit the nozzle of an hydrometer to be inserted. Before talcing a sample, tilt the battery to bring sufficient electrolyte above the separators. If the level of the electrolyte is so low that an hydrometer reading cannot be taken, no attempt should be made to take a reading after adding distilled water until the battery has been on charge for at least 30 minutes.

Measure the specific gravity of the add in each cell in turn. The reading given by each cell should be approximately the same; if one cell differs appreciably from the others, an internal fault in that cell is indicated.

Specific gravity readings and their indications are as follows:

|

Climates under 90°F.

|

Climates over 90°F.

|

|

|

1.270—1.290

|

Cell fully charged

|

1.210—1.230

|

|

1.190-1.210

|

Cell about half discharged

|

1.130—1.150

|

|

1.110—1.130

|

Cell fully discharged

|

1.050-1.070

|

The appearance of the electrolyte drawn into the hydrometer when taking a reading gives a useful indication of the state of the plates; if it is very dirty, or contains small particles in suspension, it is possible that the plates are in a bad condition.

Discharge Test

Motor-cycle batteries must not be subjected to the heavy discharge test, as recommended for motor-car and commercial vehicle batteries.

Recharging from an external supply

If the hydrometer test indicates that the battery is merely discharged, and is otherwise in a good condition, it should be recharged, either on the motor-cycle by a period of daytime running, or on the bench from an external supply.