CRANKSHAFT RE-GRINDING.

It will be necessary to re-grind the bearing surfaces of the crankshaft when the overall wear of the crankpins or gear side journal exceeds .002", or if the surfaces have been damaged by bearing seizure. Worn bearings will develop a distinct "knock" and the engine will become generally rough. Suitable undersized big end bearing shells and gear side bushes can be supplied for crankshafts ground to the dimensions shown.

The crankshafts fitted to A7 models having engine numbers from XA7-101 to XA7-600 have crankpins of larger diameter than those fitted to later models. Provision is made for one re-grind only on this earlier crankshaft, after which connecting rods 67-1200 and standard bearing shells 67-320 must be fitted. No subsequent re-grinding is recommended.

Although only the left-hand connecting rod is drilled for lubrication purposes, all shells are now drilled for standardisation. The plain shell 67-226 is no longer being supplied.

The following tables give dimensions of reground bearings, for both crankshafts, together with the part numbers of undersize shells and bushes. These numbers must be quoted when ordering.

| Engine Nos. XA7-101 to XA7-600. First Regrind. | |||||

|

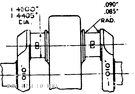

Grind the crankpins to 1.4600" - 1.4595" with a .090"/.085" face radius both sides. This is the standard dimension on machines Engine Nos. XA7-601 upwards

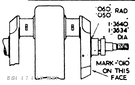

Fit connecting rod assembly 67-1200(2) with standard bearing shell 67-320(4). Mark webs as shown.

|

|

||||

| Engine Nos. XA7-601 upwards and A10 Models. | |||||

|

CRANKSHAFT ASSEMBLIESPart No. 67-384Part No. 67-664

|

CRANKSHAFT ASSEMBLIESPart No. 67-1149Part No. 67-121A

|

||||

|

FIRST REGRIND

|

|||||

|

Grind the crankpins to 1.4500"/1.4495" diameter with .090"/.085" face radius. Fit bearing shell 67-244 (4 off) marked .010" undersize

|

|

Grind the crankpins to 1.677"/1.6765" diameter with .120"/.115" face radius. Fit bearing shell 67-1177 (4 off) marked .010" undersize

|

|||

|

SECOND REGRIND

|

|||||

|

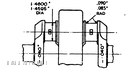

Grind the crank pins to 1.4400/1.4395" diameter with .0907 .085' face radius. Fit bearing shell 67-245 (4 off) marked .020" undersize.

|

Mark crankshaft web face as shown

|

Grind the crankpins to 1.667”/1.6665' diameter with .120/.115" face radius. Fit bearing shell 67-1178 (4 off) marked .020' undersize.

|

|||

|

THIRD REGRIND

|

|||||

|

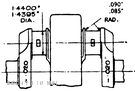

Grind the crankpins to 1.4300"/1.4295" diameter with .090"/.085" face radius. Fit bearing shell 67-246 (4 off) marked .030" undersize

|

Mark crankshaft web face as shown

|

Grind the crankpins to 1.657"/1.6565" diameter with .120"/ .115" face radius. Fit bearing shell 67-1179 (4 off) marked .030' undersize.

|

|||

|

GEAR SIDE JOURNAL

|

|||||

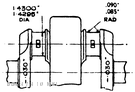

Mark crankshaft web face as shown Mark crankshaft web face as shown |

Grind the journal 13640"/1.3634" with .060"/.050" face radius.

Fit .010" undersize bush 67-799 (use bush 67-652 for engines XA7 -101 to XA7-600).

|

||||